Communication wiring technicians with tenure have witnessed horror stories of labelling gone wrong. It seems like such a minor part of the project until you realize the implications of an error or lack of accurate labels and documentation. There have been major outages caused and recovery delays due to an incorrect or non-existent label. Everyday work is being done on live equipment and we must rely on a diverse circuit to carry traffic. If that label is wrong, it can lead to isolating a switch or router; then traffic comes to a stop. Our industry depends on keeping customers connected. If we don’t strive for 100% reliability by proper planning and documentation the promise of 99.999% reliability is out of reach and we won’t have those customers for long.

- Labels need to be simple and easy to read. There have been dozens of formats tried using all sorts of technology from bar coding that requires a scanner to unique digits that require a reference manual. The last thing someone needs while troubleshooting is un-necessary steps slowing them down while trying to get a service restored.

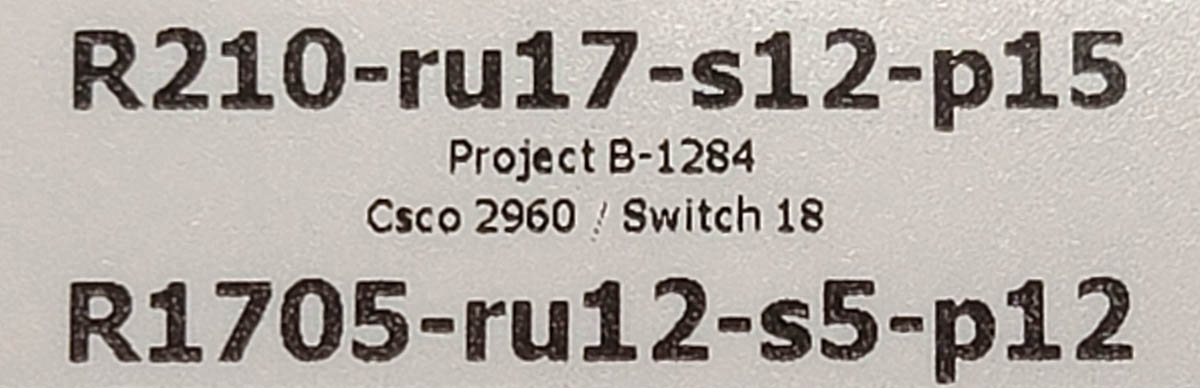

- Labels in an easy-to-read format have worked the best and don’t cause more complication. Source and destination formatting is the simplest way to accurately identify cables. A label that plainly says R201-ru17-s12-p15 is self-evident. It is starting out in Rack 201, elevation 17, slot 12 -port 15 of a device. Anyone should be able to find that location based on this information.

- The next piece of information is the destination. Using the same format, we can use R1704-ru12-s5-p12. Now the far end of the cable is easy to find. It can be helpful to add more information such as connected device names. It can be a network name such as “Switch 18” or the actual device such as Cisco 2960. Some network operators like to see one more piece of information such as a plan number. This information can relate back to the original installation documentation. Having this will allow a tech to refer back to the overall network plan showing all elements of a platform.

A complete cable label incorporating all this information would look like this:

I hope this helps your network reliability.

BIAC Operational Efficiency Team Lead, Al Stephenson